Samsung washing machine detailing device, description and assignment of units

The structure and equipment of all Samsung washing machines has common features.

The structure and equipment of all Samsung washing machines has common features.

The set of structural elements includes both complex electronic modules and sensors, as well as mechanical parts necessary to maintain the well-coordinated operation of the unit.

Knowledge of the device of a household appliance allows you to understand the problems that arise and eliminate them yourself. What is the structure of the Samsung washing machine, we will tell in the article.

Content

How does the Samsung automatic machine work?

The latest Samsung technologies, which are used in the manufacture of automatic washing machines (CMA), make them complex mechanisms. However, upon closer examination, the design of the unit is easy to understand.

The body of any model consists of:

- front panel,

- back wall,

- bottom and cover.

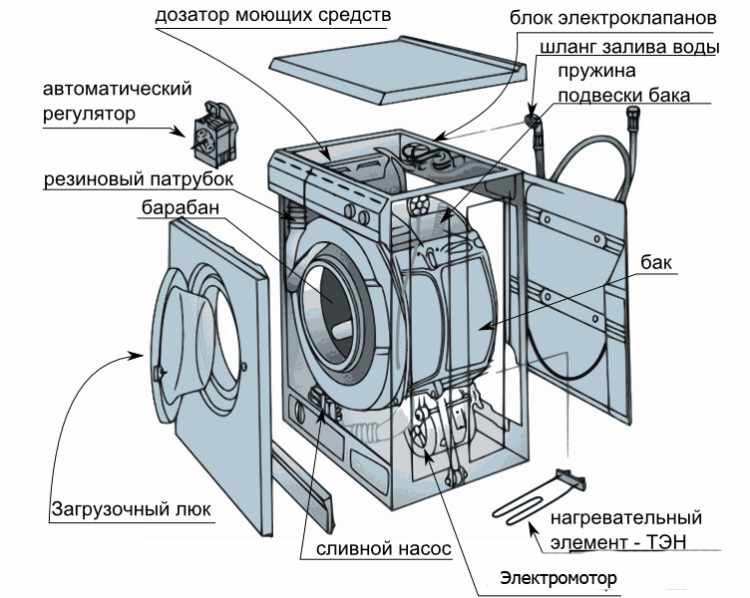

The external and internal parts of the unit are located according to the following diagram:

- On the front side - control panel, powder tray, drain pump, hose, filter.

- From the top panel - an inlet valve, level switch, tank suspension in the form of springs, counterweights.

- On the front side there is a tank, shock absorbers.

- Rear side - drive belt, motor, pulley, power cord, drain hose.

The internal filling of a technical product includes basic and additional devices. The main ones are:

- control module;

- electric motor;

- tank;

- Heating element;

- electric pump.

Control module

This unit in the washing appliance is the main electronic part. The control module is a kind of "brain" of an automatic machine, it includes the display panel and the software module itself.

The power unit provides power supply and control of all performed functions. This is possible due to the connection of all sensors, electronics and actuators to the control unit. When defects arise in the machine, the signal goes to the electronic board and is reflected on the panel in the form of flashing indicators or a code on the display.

The electronic board is very susceptible to voltage surges, therefore, for the flawless operation of the washing machine, a device is needed to protect it from power surges.

Motor and tachogenerator

These two important components in a washing machine work in pairs. The electric motor provides the drum rotation specified by the mode.

The collector type motor is localized in the lower part of the SMA... He manipulates the drum through a special belt that is attached to the motor shaft and drum pulley. This design leads to periodic wear of the electric brushes and the need for more frequent repairs.

The tachometer monitors the number of revolutions. The tachogenerator sends the result of its tracking to the control module, which checks the speed according to a given program.

Level sensor and filling valve

These details also work synergistically. The purpose of the pressure switch is to control the volume of water poured into the tank... Outwardly, this element is a round box with wires, fixed under the cover of the machine body.

The level sensor detects the pressure in the reservoir and sends the information to the control module. The latter, upon receiving a sign of a sufficient amount of liquid, sends an order to the filling valve to stop drawing water.

The valve responsible for the flow of water from the water pipe has one, two or three coils... The voltage that is applied to them after a corresponding signal from the control module causes the diaphragm in the inlet valve to open. When the voltage drops, the diaphragm valve closes and shuts off water access.

Tank and drum

A washing machine tank is a sealed plastic container filled with water. Inside it is a metal drum in which the laundry is placed.

This part of the unit has special devices to improve the quality of washing:

- corrugated protrusions;

- plastic ribs;

- perforations in the walls.

The maximum load of the machine depends on the size of the drum. This parameter differs in different Samsung models.

The rotation of the drum is carried out due to the bearing built into the tank and the fixed shaft and gear pulley.

Heating element and thermal sensor

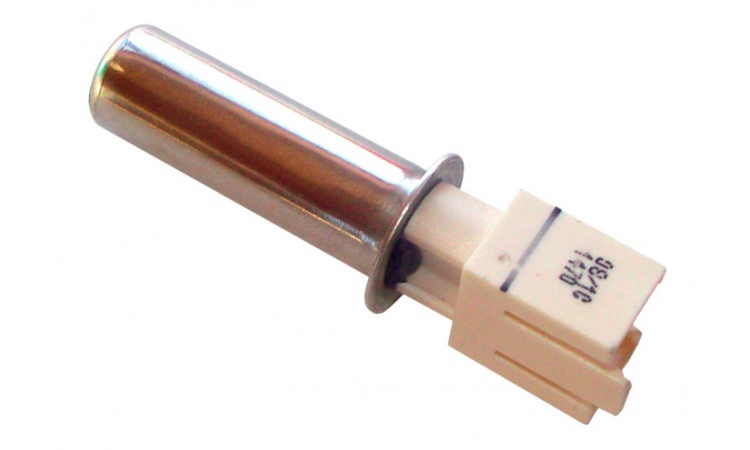

The heating element (TEN) is located at the bottom of the machine under the tank... This part provides heating of water during washing up to the set temperature. The heating element receives the command about the required temperature level from the control module, after which it is switched on.

Heating is controlled by a temperature sensor (thermostat or thermistor), which is built into the heating element housing. Outwardly, it looks like a metal tube. When the required temperature level is reached, the temperature sensor sends a signal to the control unit, which in turn turns off the heating element.

Gas-filled thermostats are connected via a tube to the temperature sensor of the control panel. The closure of the contacts occurs as a result of the expansion of the heated freon inside the tube.

The second type of thermal sensors is thermistors, work by measuring resistance during water heating. These devices are considered to be more advanced and reliable. They are used in the assembly of technologically advanced modern Samsung models.

Springs, shock absorbers and counterweights

These structural elements are designed to neutralize vibration and "bouncing" of the washing unit during the spin cycle. Vibration dampers consist of a piston and a tube.These parts are fixed on the side wall of the body and the bottom of the tank.

Springs hang down from the top and keep the tank suspended... The life of the bearing and belt depends on the quality and condition of the shock absorbers.

Counterweights (or in other words, weights) are concrete or plastic stones located at the bottom of the back of the machine. They keep the tank in balance. Despite their massiveness and integrity, these parts can also be damaged during operation.

Breakage is often caused by a cracked counterweight or loose bolt... In the latter case, the rattling of the device is eliminated by tightening the fasteners.

Locking device and cuff

The mechanism that keeps the door closed is essentially an electronic lock. The hatch is first closed mechanically by snapping in the latch. After activating the preset program, the door is electronically locked, which is accompanied by a soft click.

The hatch lock device guarantees accidental opening of the door during the operation of the SMA... Unlocking occurs after the end of the program upon receipt of the corresponding command from the control module.

The cuff also serves as a protective role against possible leaks through the gap between the hatch door and the tank. Outwardly, it looks like a rubber seal. This accessory must always be in satisfactory condition: clean, dry, free from cracks or other damage.

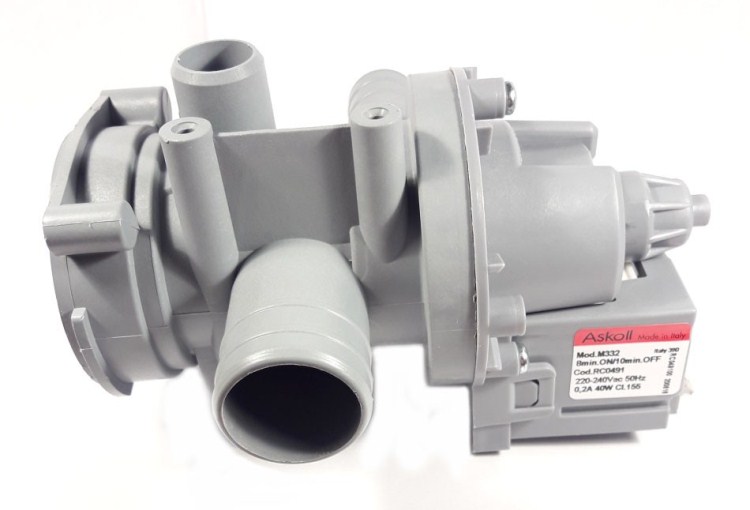

Pump, snail, filter

A pump is provided to pump out dirty water from the tank after washing or rinsing. There are two types of drip in Samsung washing machines: synchronous and asynchronous.

There are two main elements in the design of any pump:

- Motor

- Impeller.

A so-called cochlea is attached to the upper (or front) part of the pump. It is required to connect the drain hose.

In the same part, a filter is fixed that filters out debris. The pump blades, perpendicularly fixed on its axis, start moving when the rotor is started.

Small objects may fall into the pump, filter and hose when draining waste fluidleft in clothes (paper clips, coins, buttons). This leads to pump failure and the need for repair.

Hoses, pipes

These parts are designed for filling water into the tank and draining the waste liquid. The length of the hoses depends on the location of the machine and its distance from the sewer and water pipes. If it is necessary to reinstall the machine at a distant distance, longer tubes are used.

The hoses are located on the outside of the body, while the nozzles are on the inside... The inlet and outlet pipes work in perfect harmony and provide an unobstructed flow of water.

The new hoses and fittings are flexible and flexible. The appearance of cracks, deformations, drying out threatens with leaks, therefore, failed trunk elements must be replaced in time.

Powder receptacle

The dispenser is a container with different compartments for powder and conditioner... Detergents are loaded into the powder receptacle before starting the program and stored there until the desired wash phase begins.

After turning on the soaking or washing mode, water enters the compartment with the powder and rinses it into the tank. When the final rinse is initiated, water is poured through the fabric softener compartment.

Conclusion

Samsung washing machines are constructed of many important parts and components, each of which serves a specific purpose.

The coordinated work of all components determines the performance of the inherent functions and a long service life... Having studied in detail the device of this household appliance, you can master self-repair and ensure trouble-free operation.